Industrial Applications

Can increase machining cutting efficiency by 20-30%.

Significantly improves the odor of coolants.

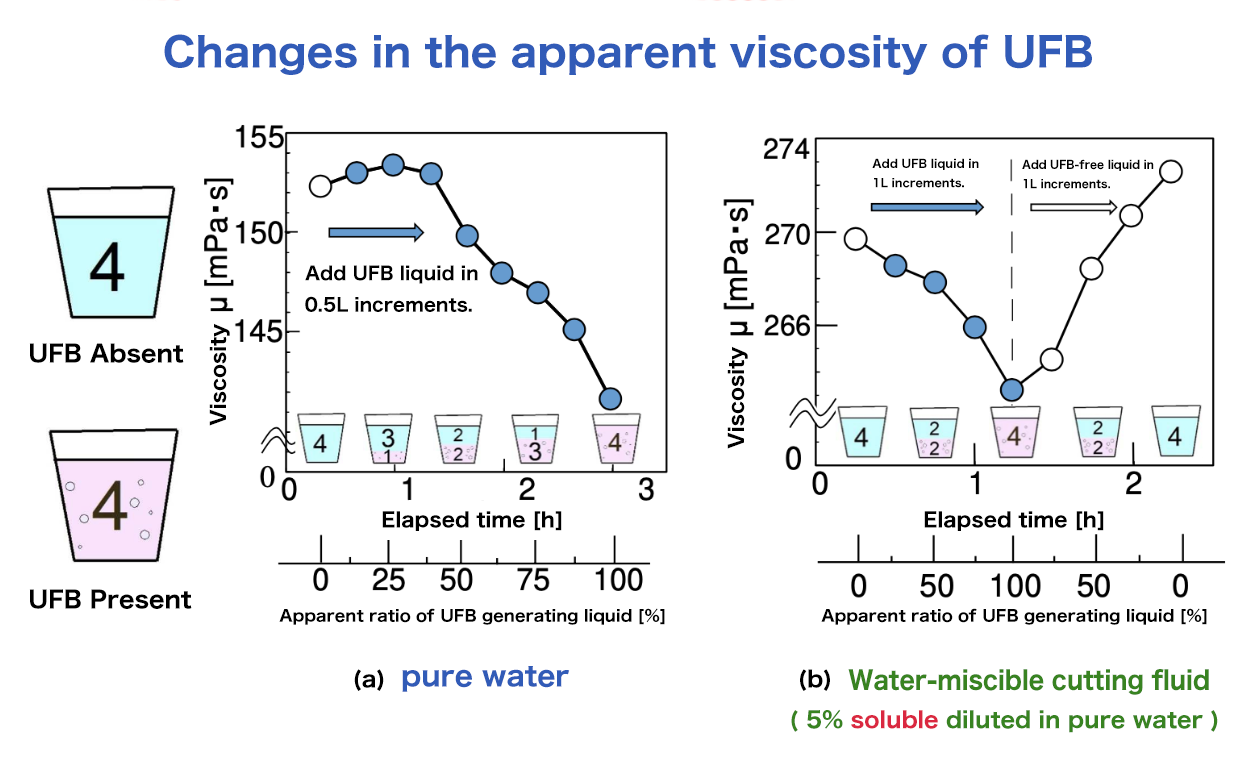

By mixing ultra-high-density nanobubbles into coolants for machining processes like metalworking, we can reduce cutting resistance and significantly improve cooling efficiency.

The wettability of the coolant is greatly enhanced.

This improves machining efficiency (e.g., time efficiency) by 20-30%, contributing to increased productivity (the improvement rate depends on conditions).

The surface finish of the workpiece after machining becomes higher quality.

Tool wear is reduced, leading to longer tool life and contributing to long-term cost savings.

Since it has the effect of preventing coolant degradation due to bacterial growth, it's possible to significantly suppress the strong odors generated by the coolant.